About VDA KLT Small Load Carriers

by DE-PACKpublished on

Precise Euronorm Carriers!

Our stackable VDA Small Load Carriers are specifically designed for logistical processes in the automotive industry. With our VDA Small Load Carriers you can protect, sort and transport components of all types between suppliers and car manufacturers. Our DE-PACK Small Load Carriers are the perfect standardized solution to meet the versatile requirements of today's warehousing and transportation needs.

VDA Small Load Carrier System

The standardized design features of a VDA-Small Load Carrier expedite the economical use of transportation, storage and conveyor technology. The Small Load Carrier’s ergonomic design makes it easy to carry and move by hand. The VDA-R-Small Load Carriers (interlocking carriers) can be stacked and interlocked making for a very stable load and eliminating the need for other stabilization measures (i.e.: straps, shrink wrap).

The smooth and straight inner walls of the VDA-Small Load Carrier make it ideal for automated filling. Small Load Carriers allow for damage-free transportation of your product. You can also decrease your storage and staging areas because there is a readily available “user pool” of containers in the supply industry.

The VDA-Small Load Carrier system also maximizes your flexibility in managing your consumables and can be used for waste management or recycling management. A flexible system that is customizable to ensure a smooth process for any appropriate application.

The VDA-Small Load Carrier industry uses uniform parameters for production and quality control to assure consistency across manufacturers. Regardless of the manufacturer, VDA-Small Load Carriers must be compatible to each other. Manufacturers are also required to take back damaged system elements and recycle them.

VDA-Small Load Carrier systems avoid waste and conserve resources by eliminating disposable exterior and interior packaging.

Variations

TYPE VDA-R-SMALL LOAD CARRIER

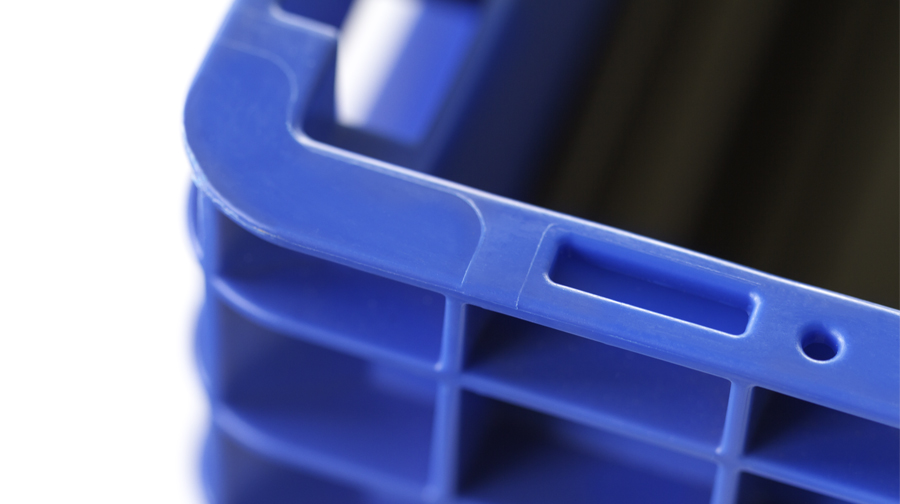

The VDA-R-Small Load Carriers (interlocking carriers) can be stacked and interlocked making for a very stable load and eliminating the need for other stabilization measures (i.e.: straps, shrink wrap). The bottom of one carrier fits within the edges of the next carrier below. The carrier’s stacking feet prevent tipping over and allow for stacking of multiple carriers without additional stabilization measures.

The VDA-R-Small Load Carrier’s high stability is achieved by heavy duty bracing on its sides.

TYPE VDA-RL-SMALL LOAD CARRIER

The stability of the VDA-RL-Small Load Carrier is also achieved by bracing on the sides. Unlike the VDA-R-Small Load Carrier, it has a smooth bottom with water drainage holes and is rated for low to medium duty.

TYPE VDA-SMALL LOAD CARRIER-ESD (ELECTROSTATIC DISCHARGE PROTECTION)

The VDA-Small Load Carrier-ESD is used for the storage and transport of electronic components. Its product properties are identical to those of the VDA-R-Small Load Carrier and VDA-RL-Small Load Carrier, but it is made of plastic with electrical conductivity characteristics. Electrostatic discharges are conducted away from sensitive electronic components which remain well protected. VDA-Small Load Carrier-ESD are marked with a yellow ESD symbol.

Material

To ensure consistent quality, certified Small Load Carrier manufacturers guarantee that all VDA-Small Load Carrier system elements use only polypropylene (PP).

All certified Small Load Carrier manufacturers are required to take back damaged VDA-Small Load Carrier system elements and recycle them. Elements made of foam are excluded.

Alternatively, users can take the damaged elements to other recycling centers. Prior to return/recycling, the elements must be free of foreign objects such as metal elements or stickers and residues such as oil or dirt.

Only if these conditions are met are the elements suitable for the recycling process. Testing requirements for raw materials are not included in this citation. However, the finished VDA-Small Load Carrier system elements must meet the quality and test requirements mentioned in this citation.

Color tests are used to check the color tolerances of finished products. VDA-Small Load Carrier system elements must be UV-stabilized and be able to withstand washing and cleaning agents.

VDA Standard 4504 specifies the material properties for electrostatic dissipative VDA-Small Load Carrier system elements.